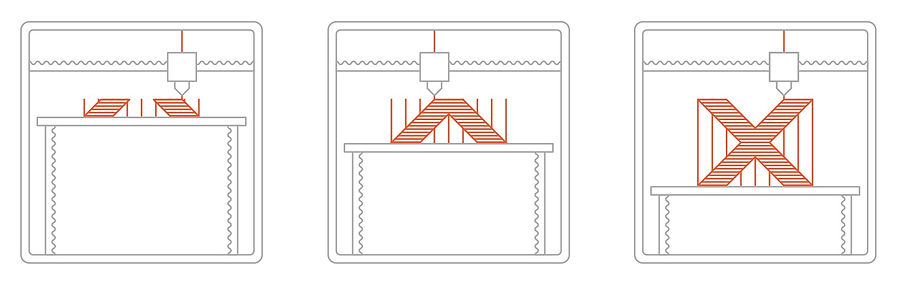

Material extrusion is a 3D printing process where a filament of solid thermoplastic material is pushed through a heated nozzle, melting it in the process. The printer deposits the material on a build platform along a predetermined path, where the filament cools and solidifies to form a solid object.

Fused Deposition Modeling (FDM)

Also known as Fused Filament Fabrication (FFF).

Materials

Thermoplastic filament (PLA, ABS, PET, TPU).

Dimensional Accuracy

±0.5% (lower limit ±0.5 mm).

Applications of CFD:

Electrical housings

Form and fit testing

Jigs and fixtures

Investment casting patterns

Strengths

1. Best surface finish

2. Full color and multi-material available

1. Brittle, not suitable for mechanical parts

2. Higher cost than SLA/DLP for visual purposes

Are you looking for complete 3D printing rapid prototyping services? Forcyst is your one-stop solution. Our experts will help you with different prototyping methods, from SLA and SLM to Drop on Demand and SLS, tailored to your requirements.

Forcyst, India’s leading design engineering and rapid prototyping company based in Mumbai, offers comprehensive product design and development solutions. From concept design and research to 3D printing and manufacturing, we serve multiple sectors, including medical, automotive, oil & gas, and more.