What is Computational Fluid Dynamics (CFD)?

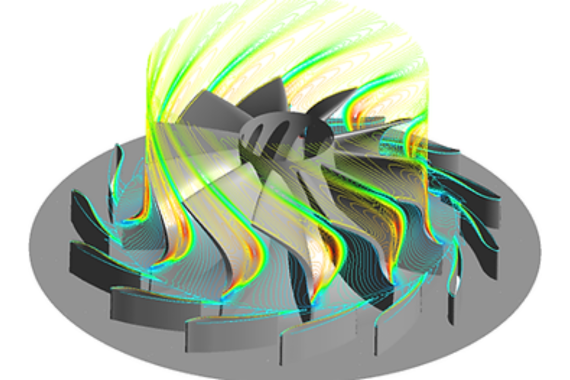

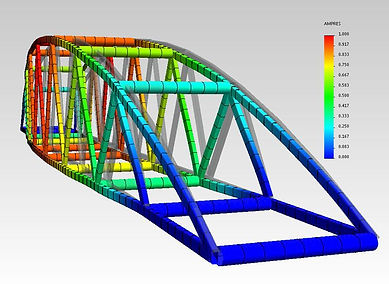

Computational Fluid Dynamics (CFD) is a cutting-edge design and analysis method used to solve problems involving fluid flow across a profile, within a component, or inside a system.

How Does CFD Help in Product Design?

At Forcyst, we use CFD simulation software to validate our concepts and designs. This powerful tool allows us to see how fluid flows through or around a product at various temperatures and speeds. It’s especially useful for products with pressure changes at multiple points, heat variations at inlets and outlets, and the overall effect of fluid flow on the entire component or system.

Why Use CFD?

While adding CFD to the product development process can increase upfront costs, it ultimately saves money by reducing the need for repeated prototypes and extensive testing. By using CFD, we can achieve higher success rates compared to traditional design methods. This approach has proven successful in industries such as automotive and medical, where we have enhanced the effectiveness and efficiency of various products.

Our CFD Process

1. Understanding Requirements

Our team of qualified engineers starts by understanding the client's needs and defining the problem statement.

2. Setting Boundary Conditions

We set the necessary conditions for the analysis.

3. Conducting CFD Analysis

Using advanced CFD software, we perform the analysis and generate a detailed report to validate the performance of the designed product.

Benefits

Increased Insight

CFD provides a deeper understanding of systems that are hard to prototype or test in R&D.

Early Problem Detection

Identifies performance issues during the design process, allowing for timely changes and optimization.

Accurate Predictions

Precisely predicts mass flow rates, pressure drops, mixing rates, heat transfer rates, and fluid dynamic forces.

Applications of CFD:

Aerodynamics

Industrial Fluid Dynamics

Fluid Structure Interaction

Heat Transfer

Hydrodynamics

Accurate and meaningful CFD simulations require highly skilled and experienced engineers. While modern simulation software is powerful, the quality of the output depends on the accuracy of the data input. Our team is adept at identifying anomalies and will supplement the data with hand calculations when necessary.